Category: press

Textiles and alternative energy

June 10, 2024 | Textile Technology Source | By: Debra Cobb

From solar and wind, to carbon capture, textiles contribute to cleaner power.

According to the International Energy Agency (IEA), the amount of renewable capacity added to energy systems around the world grew by 50 percent in 2023, reaching almost 510 gigawatts (GW), with solar PV accounting for three-quarters of additions worldwide.

The IEA forecasts that U.S. solar power generation will grow 75 percent from 163 billion kilowatt hours (kWh) in 2023 to 286 billion kWh in 2025. They also expect that wind power generation will grow 11 percent from 430 billion kWh in 2023 to 476 billion kWh in 2025. Hydrogen power and sustainable aviation fuel (SAF) are also poised for growth.

The economic opportunities provided by the generation of alternative energy, requiring new facilities, new materials and a wide range of feedstocks, could likewise fuel the growth of innovative and technical textiles. Seen and unseen, these critical components include unique polymers, composites, membranes and filters, as well as performance textiles for wind and solar that are lighter, stronger and often recyclable.

From solar cells to solar fabric

Recent developments in light weight, super-thin, flexible photovoltaics have enabled the solarization of fabrics, expanding the potential range of energy-producing form factors. Brooklyn-grown Pvilion laminates their solar cells to a variety of textiles to create a range of canopies, tents, curtains, building façades backpacks and clothing. “Once you have the panel, you can turn it into anything,” says Colin Touhey, the company’s co-founder and CEO.

Pvilion’s advantage is in its systems that provide both shelter and power in one structure to partners such as Carnegie Hall, Bloomberg, Tishman Speyer, The City of New York, Yale University, the U.S. Air Force, the Florida Dept. of Transportation and The City of Miami.

“Solar fabrics are getting better and better,” Touhey says. He explains that the company is agnostic regarding substrates, focusing instead on durability and longevity. Pvilion creates solar fabrics from rip-stop nylon, PVC-coated polyester, PTFE-coated fiberglass, Dyneema, and perhaps stretch substrates. “We care about quality,” he continues, pointing out that it is critical for Pvilion’s projects for the U.S. military, which also requires fabrics to be made in the U.S.

“We are more and more trying to build a line of finished product, as mass production is the goal for price,” says Colin. “But we are happy to work with people who have small volume. Being a solar power company doesn’t mean anything if it doesn’t fit into the customer’s requirements.”

From sails to wind turbines

A Scottish start-up called ACT Blade is revolutionizing wind power with an innovative fabric and specialized modular manufacturing system for turbine blades.

The new blades are longer in length without increased weight, and comprise fewer materials and simpler, streamlined production methods. They feature a slender supporting structure made from a composite material that is completely covered by the technical textile.

The protective outer shell for the wind turbine blades was manufactured by Concordia Textiles Group, based in Belgium. The fabric is reparable and is composed of elements that can be easily separated for recycling at end of life.

According to Rik Gekiere, Concordia’s sales and product manager, “We developed a laminate that is the common denominator of more than twenty technical requirements, by combining the strength and elasticity of a fabric with a protective layer. Rain erosion resistance and durability over time were the most challenging to achieve. We prefer to wait to provide more details of the product until the actual market release of the blades.”

ENEL Green Power S.p.A., an Italian multinational renewable energy corporation, is partnering with ACT Blade to develop the project.

A wind technology called OceanWings®, developed by VPLP Design in France, is said to enable a 45 percent savings in fuel consumption and a subsequent reduction in CO2e for sailing vessels. The vertical windsails provide aerodynamic lift and feature automated positioning to maximize thrust.

OceanWings are made from eco-composites that include linen fiber and recycled thermoplastic resins. The outer bag is 1000 denier nylon, with a layer of urethane to protect against punctures and abrasion.

The sails were first trialed in 2019 on the Energy Observer, an experimental vessel designed to test alternative energy sources in maritime conditions. In 2022 the commercial wind-powered cargo ship, the Canopeé, launched with four OceanWings that reduce fuel consumption by up to 42 percent in good weather conditions.

Green hydrogen: fuel of the future?

The World Economic Forum defines green hydrogen (H2) as hydrogen produced through electrolysis, usingrenewable electricity from solar or wind to split water into two hydrogen atoms and one oxygen atom. Green hydrogen can be used to decarbonize transportation, including heavy trucks, aviation and shipping, as well as in the manufacturing of steel, cement and other hard-to-abate industries.

At the heart of the green hydrogen process are proton exchange membranes, or PEMs. These membranes play a vital role in H2 production, fuel cells, and flow batteries for energy storage. The Chemours™Company, based in Wilmington, Delaware, dominates this market with their Nafion™ brand portfolio of membranes, dispersions, and resins.

Nafion is a synthetic polymer with unique ionic properties, created by incorporating perfluorovinyl ether groups terminated with sulfonate groups onto a tetrafluoroethylene (PTFE) backbone. The resulting product is a thermoplastic that can be extruded or solution-cast into films for composite membranes.

In response to a request for information, Nafion portfolio’s product manager referred to a paper published by Chemours’ technical team: “Advancements in Thin, Reinforced Proton Exchange Membranes for Water Electrolysis” by Ryan Gebhardt, et al.

“Employing a thinner and mechanically supported membrane can enhance both the electrochemical performance and mechanical properties. With the demand for cheaper hydrogen, these new membrane designs are needed to achieve advanced performance metrics,” it says.

While the green hydrogen economy is still in its infancy, the U.S. Dept. of Energy (DOE) recently announced $750 million, funded by the 2022 Bipartisan Infrastructure Law, for 52 projects across 24 states to reduce the cost of clean hydrogen. According to the DOE, clean hydrogen is set to play a vital role in reducing emissions from the most energy-intensive and polluting sectors of the economy.

For example, Airbus is testing the use of hydrogen fuel cells to generate electricity to power aircraft that fly with almost zero emissions. Airbus’ ZEROe project hopes to bring the world’s first hydrogen-powered commercial aircraft to market by 2035. Flight testing of the fuel cell propulsion system on an Airbus 380 is scheduled for 2026.

Decarbonizing aviation with SAF

The airline industry uses about 20 billion gallons of jet fuel every year, and globally aviation accounts for 2 percent of all CO2e and 12 percent of CO2e from transportation, according to the DOE.

Sustainable aviation fuel (SAF) reduces emissions from air transportation, and when blended with conventional aviation fuel is a drop-in for today’s aircraft and infrastructure. Depending on the feedstock and blend, SAF can reduce aviation’s CO2e by up to 80 percent.

There are several pathways to making SAF, based on various feedstocks. These include sustainably sourced renewable waste such as cooking oil and animal fat; biomass, such as agricultural and forest wastes and solid municipal waste; and power-to-liquid SAF made from captured CO2.

“Sustainable Energy Generation from Textile Biowaste and Its Challenges,” a paper by Khandaker, et al., Dept. of Textile Engineering, Dhaka University of Engineering & Technology, Bangladesh, reports that waste from the textile industry could also be a significant source of biomass for fuel.

LanzaJet, a sustainable fuels technology company spun out of LanzaTech in 2020, produces ethanol alcohol-to-jet SAF from any source of low-carbon ethanol, including biomass, industrial waste, municipal solid waste (MSW), and CO2. The company’s recently opened Freedom Pines facility in Soperton, Georgia, supported by DOE’s Bioenergy Technology Office (BETO), will produce nine million gallons of SAF and one million gallons of renewable diesel in its first year of operations.

LanzaJet and Tadweer, (Abu Dhabi Waste Management Company) are cooperating in a feasibility study to initiate SAF production from municipal and commercial solid waste. The hope is that up to 350,000 metric tons of hard-to-recycle municipal and commercial solid waste can be transformed into 200,000 metric tons of ethanol per year.

Tadweer’s facility will transform solid waste streams into a synthesis gas consisting of CO, CO2 and H2, via a gasification unit licensed by sustainable technology solutions provider NextChem, part of MAIRE Group. The gas stream is then transformed by LanzaTech’s microbe-powered bioreactor into CarbonSmart™ ethanol, which LanzaJet can then convert to SAF.

Renewable energy is a growth industry, accounting for 90 percent of all new electricity installed each year, worldwide. While it’s early days, there are opportunities for the textile industry to be involved.

A battery in a balloon

A company called Energy Dome, based in Milan, has developed a thermodynamic method of long-duration energy storage in a “battery” that uses CO2 stored in a huge fabric dome, like a balloon, made of PVC-coated polyester.

Energy from a local grid or nearby solar farm compresses the CO2 into a liquid during the day. At night, the liquid CO2 expands back into gas, driving a turbine that produces electricity and sending it back to the grid.

Energy Dome already has its first US installation planned for 2026 in Columbia County, Wisconsin, with Alliant Energy, and it has recently opened an office in Boston with a “growing ambition to decarbonize the world with our CO2 Battery™ technology.”

Debra Cobb is a freelance writer based in North Carolina with special expertise in the textile industry. She is a frequent contributor to Textile Technology Source.

To view the original article, click here.

Quiet on Set!

Why film sets are making the shift away from loud, polluting generators.

Pvilion Blog | June 24, 2024 | By Julia Fowler

From cameras to craft services and sets to studio lights, it’s no question that the entertainment industry is a massive source of global pollution. As more production companies become increasingly aware of the harmful environmental effects of their productions, many companies are beginning to take measures to reduce their impact. Thanks to several mainstream publications shining light on the harm caused, more effective action is beginning to take place than ever before.

To name a few, Disney, Netflix, and RMI have recently made public commitments to specific sustainable goals, including replacing diesel generators with clean mobile power solutions. In fact, the need is so great that there are now agencies dedicated to improving sustainability efforts on film sets. Companies like EcoSet and Earth Angel are hired by production companies to introduce strategies and solutions to reduce their carbon footprint.

While waste reduction and recycling are beneficial, the greatest offender on sets are the emissions released from fuel used for power. The generators used to power sets are releasing millions of metric tons of C02 every year. As a result, experts are suggesting eliminating the need for generators as much as possible.

Recently TIME shared an article, Film and TV’s Carbon Footprint Is Too Big to Ignore, that takes a closer look at the impact of the entertainment industry’s carbon footprint. “Every year, the global entertainment industry generates millions of metric tons of CO2. Depending on the size of the production, movies can emit on average between 391 metric tons for a small film and up to 3,370 metric tons of CO2 equivalents for large, tentpole productions such as Oppenheimer or Barbie—that’s the equivalent of powering 656 homes for a year,” according to the article.

Not only are these emissions incredibly harmful to the environment, they are harmful for the crew working around them. A 2019 study conducted by the Institute for Health Metrics and Evaluation’s Global Burden of Disease found that air pollution was the third highest ranking risk factor of diseases that resulted in death globally. Other studies – like those by Energy Report – have found that the average diesel generator emits fumes that contain over 40 toxic air pollutants, most of which are carcinogenic. Dangerous fumes are only part of the risk associated with working around generators; they are also a major source of noise pollution. Most generators emit anywhere from 85 to 105 decibels and are a common cause of hearing loss for those that spend time around them.

This is why experts recommend shifting to more sustainable options, like batteries. Batteries can be used in conjunction with solar systems. Solar powered batteries are an optimal source of clean energy, flexibility, and can provide power independent from the grid. Not only this, but thanks to the recently passed Inflation Reduction Act, solar powered battery systems qualify for a 30% tax credit.

How Can Pvilion Help?

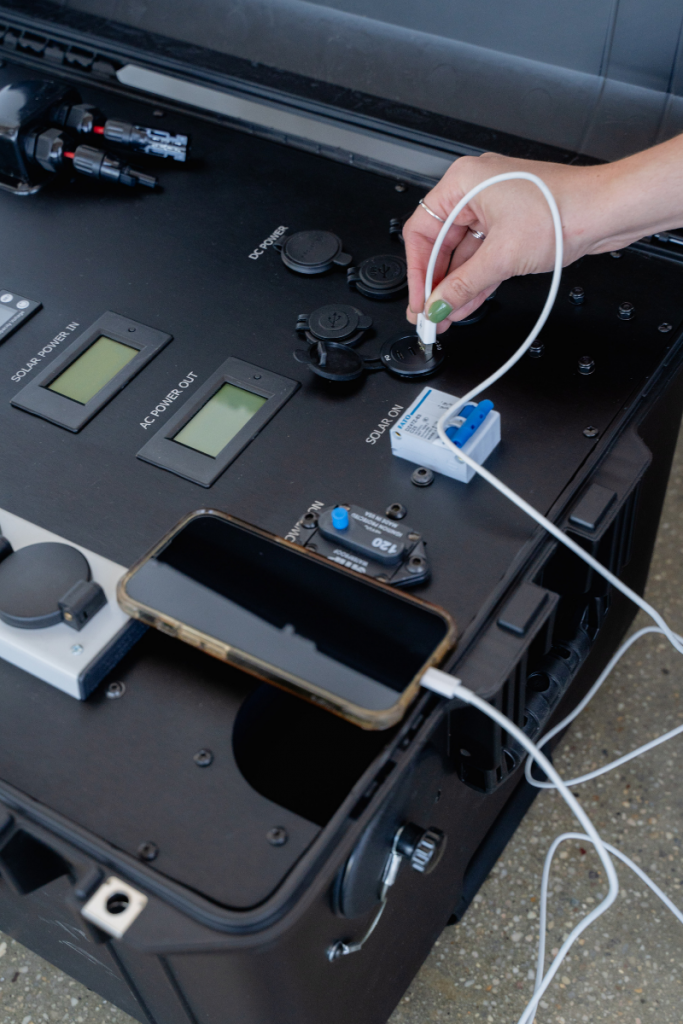

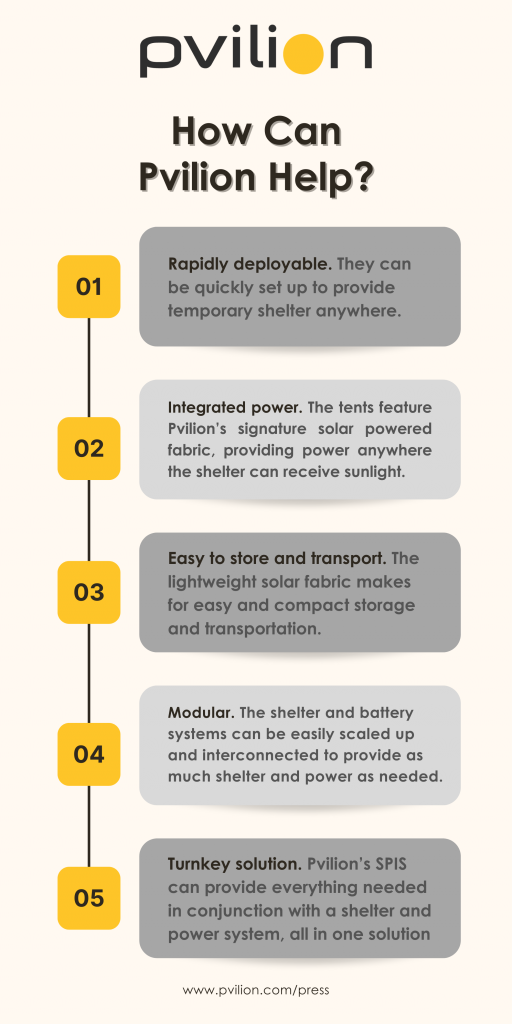

From lighting, to makeup trailers, catering, and everything in between, the demand for reliable off-grid power on a production set is high. Pvilion works with production companies to provide battery kit solutions that exceed the expectations of a traditional generator. Pvilion battery kits are:

- Completely silent. None of the loud and excessive noises associated with diesel generators.

- Eco-friendly. The systems release zero-emissions.

- User Friendly. Batteries are designed to be easily used by anyone, without the need of an expert.

- Modular. They can be scaled up or down to meet power needs.

- Easy to stack and move. They are integrated with durable Pelican cases.

- Solar-ready. They can be used as-is or can connect to a solar source. Solar allows for sustainably sourced power without needing to re-fuel or connect to the grid. (Perfect when paired with a Pvilion Solar-Powered Fabric Shelter, which could qualify them for a 30% incentive tax credit.

Interested in using a Pvilion battery on your next production? Pvilion offers battery rental kits for purchase with or without a complete solar fabric system. For businesses located in New York City, Pvilion offers a battery rental program – with the option for daily on-site delivery. Rentals can be scaled to meet power need and can be rented on a short-term or long-term basis. Want to learn more? Get in touch with our battery rental team for

Pvilion Helps Rooftop Vineyard Celebrate the New Season in Brooklyn

April 7, 2024 | Welectric

Brooklyn’s iconic Rooftop Reds vineyard takes sustainability to new heights this spring, teaming up with local innovator Pvilion to introduce solar-powered shelter and energy solutions.

Pvilion, a small business specializing solar-powered fabric, is helping fellow Brooklyn-based business, Rooftop Reds, ring in the spring season with some solar-powered shade and power for visitors of the rooftop vineyard and wine bar.

Located in the Brooklyn Navy Yard, Rooftop Reds is the first of its kind and the only rooftop vineyard in New York City. With views of the Manhattan and Brooklyn skyline, it’s a popular spot for guests to enjoy a glass of wine with a view. That’s not all they offer, though. They have a full roster of events that visitors can attend – including movie nights, wine tastings, vineyard tours, locally sourced meals, and much more.

Rooftop Reds needed shelter for guests and power for events, and being an environmentally conscious and forward-thinking company, they reached out to Pvilion for an all-in-one solution. Pvilion designed, fabricated, and installed a solar powered fabric awning that matches the rooftop vineyard and wine bar’s aesthetic, provides enough power for events, and adds plenty of shade for guests to gather and partake in the festivities, come rain or shine.

After closing for the winter, this spring will mark the ninth season that the 15,000 square ft vineyard has been open for business and serving the community with its nearly 200 grapevines.

“Being a small business ourselves, we love getting the opportunity to support other small businesses, especially local ones! Rooftop Reds have been our neighbors for the past 10 years, until our recent move to Industry City. It’s been great to see all the incredible events they’ve been able to use our canopy to power and shelter since we installed it a couple of years ago,” said Pvilion CEO, Colin Touhey.

Pvilion is pioneering a new way of thinking about sustainability, power, and shade in the hospitality and event space. In addition to this, they have worked on projects like the Miami Bandshell concert venue, canopies at New York Botanical Garden, a rooftop event tent for Carnegie Hall, and most recently, portable solar fabric kits for the Coldplay: Music of the Spheres World Tour.

To view the original article, click here.

Solar-Powered Fabric Designer Shakes Up the Clean Tech Industry with New Manufacturing Space and Community Job Training Program

March 2024 | IT Business Net

Small Brooklyn-based solar-powered fabric company, Pvilion, has made waves for the clean tech industry with their recent expansion through the opening of their new headquarters and initiation of local clean energy job training program.

Pvilion, a small business that designs, manufactures, and installs turnkey solar-powered fabric products, began a little over a decade ago with just three founders – Colin Touhey, Robert Lerner, and Todd Dalland – and a shared vision. They viewed every surface that receives sunlight as an opportunity to feature lightweight fabric that could generate electricity.

Today, the company has a unique line of solar-powered fabric products that can do just that, as well as a team of thirteen full-time staff members to help design, manufacture, and install them. To keep up with their growing business and maintain local manufacturing, the solar fabric company recently opened a brand new 13,500-square-foot headquarters in Brooklyn’s Industry City.

The grand opening of their new headquarters marked a huge milestone for the small business. It’s opening allowed for them to partner with BlocPower’s Civilian Climate Corps program to provide green job training with neighboring Brooklyn communities. Many members of the community have had the opportunity to learn valuable clean energy manufacturing skills since the headquarters opening late last year, and four new staff members have been hired from the program to join the Pvilion team full time.

Pvilion’s products range from stand-alone solar canopies, solar military tents, grid-tied long span structures, and solar-powered charging stations to battery systems, building facades, and solar powered clothing. They have worked on projects for Coldplay’s Music of the Spheres World Tour, Home Depot equipment rental centers, rooftop vineyards, the New York Botanical Garden, Carnegie Hall, the City of Miami, Tommy Hilfiger, and many more.

Their mission is to make clean energy available in any setting – with a focus on quality, appearance, and flexibility. Pvilion’s products have been used in a wide variety of settings, including architectural, event, fashion, hospitality, disaster relief, military, and municipal spaces. To keep up with their latest projects, you can visit their website at www.pvilion.com.

To read the original article, click here.

Steps To Sustainability: Pvilion Provides Portable, Renewable, Power

Mar 18, 2024 12:44pm | By Hannah Kinnersley

Very often in the search for sustainable solutions in the live entertainment industry we focus on fixing the issue after the fact, for example, by planting trees to offset carbon emissions, or recycling items we used to throw away, like wristbands used by audiences. But the biggest problems the industry has to address in order to make it less of a carbon offender are power generation and trucking. Currently, most tours and large, live events use massive diesel generators and only have access to renewable energy if the venue has invested in solar power or is purchasing renewable power from the grid, and even then it often will not cover the energy consumption for the event. Carrying solar panels with a tour would only increase the number of diesel trucks required, canceling out any benefit. However, one US company potentially has the answer to this dilemma, and it is already an established force in other fields with clients ranging from the US State Department to the military.

Pvilion, a Brooklyn-based solar fabric manufacturer creates rigid portable structures that are self-powered, the solar panels are built into the fabric and feed into batteries, making it ideal to set up tents for refugees or military encampments. And because the panels are small and set into the waterproof and windproof material, they are unlikely to crack, can be replaced more easily than traditional solar panels, and allows the fabric to be folded up for easy transport. The state department is using Pvilion systems that pop up into a portable solar array to generate power for disaster relief, and the Air Force relies on Pvilion’s solar-power for a project in a remote part of Alaska.

Electrical engineer Colin Touhey is a founder at Pvilion, which has been around for 12 years. His business partners in the venture are engineers that design and manufacture tents—not the type you might take hiking, but the kind you find covering airport terminals and amphitheatres. By introducing renewable energy into the equation, the applications for this type of structure have multiplied, and recently the entertainment industry has taken notice.

Live Design talked to Colin Touhey about his work in this area, uses in the entertainment industry, and the potential for the future.

Live Design: You are an electrical engineer, what brought you to the tent industry?

Colin Touhey: The engineers at FTL Design Engineering (now Buro Happold) had been designing tents basically since the 1970s, when it was almost an artisanal process, you would build a circus tent and hope it didn’t fall down. The company basically brought the industry into the 21st century by introducing modeling, structural analysis, and a high-tech building sciences perspective to it. In fact, it helped write the building codes because in the US there wasn’t really a rating, you couldn’t say that a tent could withstand a 65 mile an hour wind according to a building code. It really brought the industry into the forefront and now it’s just exploded and the amount of square footage of tentage or fabric structures around the world is tremendous. I joined as an electrical engineer in the mid 2000s to integrate energy generation into the tents.

My background is in electrical engineering and I started out working with solar and wind, but basically any kind of electricity generation project was fascinating to me. I came on board as a team member and we spun off this part of the business into Pvilion.

LD: What makes your use of this material unique?

CT: We design structures that are self-reliant, they generate the most erate energy from the fabric which feeds into a battery that provides lighting, air conditioning, and heating. We can do fully off the grid or emergency power depending on the size of the project.

Since we started, the fabric for the surface of the tents has become more and more powerful and the energy consumption inside the tents got lower [because of energy efficient lighting etc] and so they have reached an equilibrium. Most of the time we can produce 100% of the power for almost all applications.

LD: There are obviously huge applications in terms of housing for refugees and medical tents or military encampments, but how can it be used for live entertainment projects?

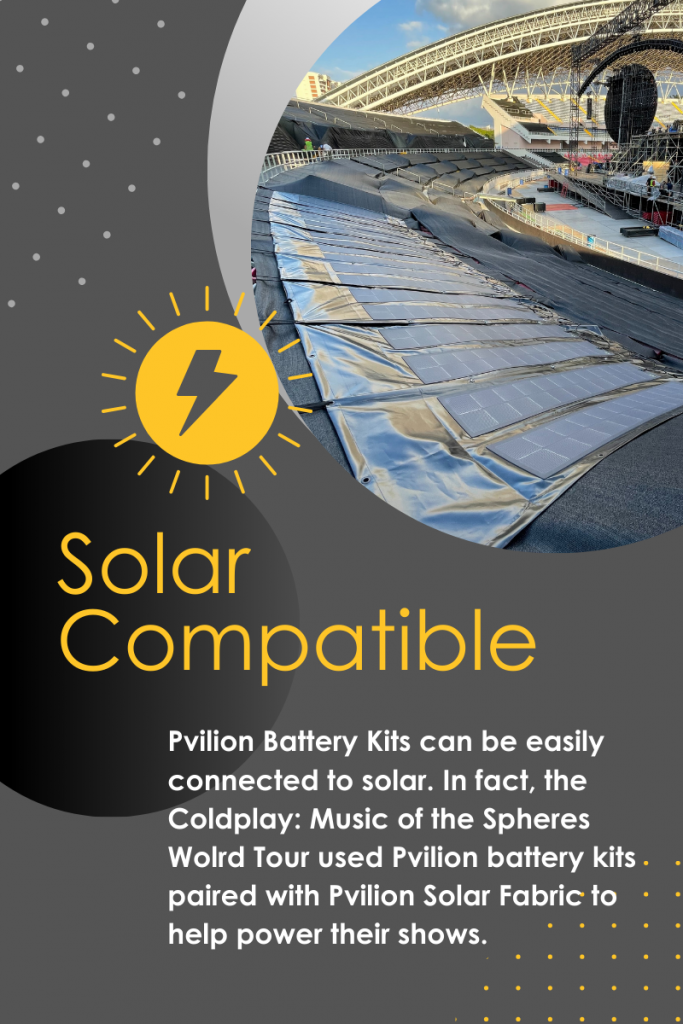

CT: There are several ways. Most recently, on the Coldplay Music of the Spheres tour, we use the fabric to cover the seats behind the stage in each stadium so that during the day it generates solar energy which feeds into a battery which in turn helps to power the show at night. It is a large piece of fabric, not seat covers in a traditional sense, and is draped over the area and then folded up and taken to the next venue. There is no reason why the fabric can’t be used be used by the venue whenever the stadium is empty but it makes more sense to use it to cover the roof of arenas and stadiums permanently. It is a much easier and more cost-effective version of traditional solar panels and can be used if there is some movement in the roof, for example a roof on a sports venue. A lot of the time there are cantilevered dome structures where you have an open center and 50 or 100 meters sticking out over the seats. The roofs are all fabric, and it could be lightweight solar fabric covering this massive area without building anything new or taking space from anything else.

So instead of running a diesel generator 24/7 for days during set up for a show, we’re basically flipping that on its head and saying let’s charge some batteries during the same period of time while the fabric is just sitting there and not creating pollution, and then discharge the battery during the concert.

On the Coldplay tour, the fabric generated about 100 kilowatt hours per day and we powered back of house and under the stage, which was around fifty people working under lights with laptops and all sorts of audio equipment and other gear. We can provide our own batteries but we didn’t for Coldplay because the tour had already partnered with BMW to provide recycled batteries.

LD: Could you get to a point where you only use a generator for two hours while the artist is on stage?

CT: You could, but the opposite would be better: not using the diesel during the concert and just running a smaller diesel generator slowly, in tandem with a renewable energy source to charge larger batteries. In theory, what you should be doing is coming to the venue with charged batteries and that way you don’t actually have to bring diesel generator trucks at all. There isn’t just one solution, there are different combinations for a solution.

Currently, there isn’t a battery out there that could power the demands of a large rock concert, but we are making baby steps toward a combination of battery and grid, and cutting down on diesel generators until we can do without them.

LD: How robust is the solar fabric? Would stadiums invest in it?

CT: When we do an architectural project it has a 25-year warranty, it is waterproof, rated for 450 mile-per-hour winds and significant weight of snow. It’s the permanent fabric that you see on projects like the Denver airport or London’s Millennium Dome [now known as The O2, designed to last 10 years and still going strong with tourists walking over the top of it and rock bands and events taking place inside it]. Our fabric is incredibly tough, Teflon-coated fiberglass, and yet you can fold it up around the solar cells like an accordion and move it around easily. A typical area of folding might be half a meter by two meters, so it would easily fit on a truck for a concert tour.

LD: Can you give a couple of examples where the fabric is in use in the US?

CT: In terms of permanent installations, in Tallahassee, Florida, we have a project called the Capital Cascades Connector Bridge. It’s a pedestrian bridge that we, designed, engineered, and installed the solar fabric for so that it generates its own lighting. The fabric also generates power for a mile-and-a-half long park there. Our products is also on the North Beach Bandshell Amphitheatre in Miami and it is used to power the lighting for that.

For temporary structures, we are renting out our systems to power summer events from clean energy sources. We’ve also built a tent on the roof of Carnegie Hall for a black-tie gala event. For small scale projects, the fabric is incredibly useful to get into non-traditional spaces and when you don’t want the noise and smell. We’re working with a traveling opera organization that should be touring this summer. For these outdoor events, rather than renting a generator, you rent a battery and a solar tent.

LD: Has there been more interest in this product since the Coldplay tour?

CT: There is more interest at the moment, and some of that is because there is legislation coming that will make it a bit harder to use generators. In California they are already banning small gas generators and a lot of emissive gas products.

LD: The obvious application to me would be festivals like Burning Man.

CT: Yes, music festivals and temporary events in cities wold benefit.

In addition to generating renewable energy, we are very, very good at structurally engineering things that use the fabric in efficient, lightweight and super strong structures that are very minimalist. Just a few poles or supports can create an incredibly strong surface. They are real rugged systems and reliable because you can’t have the lights go out for 15,000 people. Typically, at large-scale events, you have generators and back up generators, our system is very reliable, so that would be the primary power source, but the backup would be an emergency generator, not one running full time.

The other benefit is, a battery provides very consistent and high-quality power, a generator provides quite low-quality, inconsistent power, so a battery is very good for communications equipment, satellite dishes, medical applications, and things like that. If you need lighting for surgery, you don’t want a flicker.

LD: Are you actively targeting the entertainment industry? Who owns the fabric for the Coldplay tour?

CT: It is a different business model because tours typically rent everything, so Coldplay rented from PRG. Each production is custom, so getting into the supply chain is really challenging. The fabric is in the PRG inventory now, it is possible it might go out on the road again.

To read the original article, click here.

Pvilion solar canopies win BLT Built Design Award

Projects | February 1, 2024 | By: ATA

Visitors to the New York Botanical Garden in the Bronx looking for a brief respite to refuel and recharge have been doing so for the past few years under canopies that now can be called award-winning. Last fall Pvilion received recognition in the BLT Built Design Awards in one of the Landscape Architecture categories for this project. Strategically located near the botanical garden’s food truck area, the eight shade canopies have solar cells integrated into the fabric.

The New York Botanical Garden was the launch site for the company’s solar-powered canopy structures. The lightweight, turnkey canopies are fire-retardant, UV-resistant, sturdy and aesthetically pleasing—the latter of which was important to the client. Their installation was part of a pilot project funded by the Innovative Demonstrations for Energy Adaptability (IDEA) Program, an initiative of New York City’s Division of Energy Management that engaged vendors testing new or underused energy technologies. As a part of the city’s carbon emission reduction efforts, seven of the canopies contribute energy directly to the city’s power grid.

“It’s only fitting that the New York Botanical Garden, a place known for its greenery, will be leading the way with green energy technologies,” said Lisette Camilo, commissioner of the NYC Department of Citywide Administrative Services, at the time of the canopies’ installation.

The testing and demonstration time period for the canopies spanned July 2020 to December 2021. The study recorded results and listed notes for installation best practices. Because of this pilot, the canopies are popping up in other areas of the city as well, the company says, such as public library locations.

The BLT Built Design Awards program has four annual honors in landscape, architectural and interior design, and construction segments. The landscape awards in particular honor exceptional design that’s resilient, forward thinking and ecologically sensitive. “The award recognizes planning, design, management and nurturing of the built and natural environments,” the awards website notes. Open to entrants around the world and projects from the previous five years, the BLT Built Design awards are part of Three C Group GmbH, a Swiss company.

To read the original article, click here.

The Importance of Shelter and Off-Grid Power in Emergency Response

Pvilion Blog | February 23, 2024 | By Julia Fowler

In any emergency, two of the most essential tools are shelter and power. Without first meeting the need for shelter and power during times of crisis, individuals are left vulnerable, and emergency responders cannot treat the community as safely until they are in place.

Types of Disaster

Disaster can strike anywhere at any time. This map from the American Red Cross demonstrates where different types of natural disasters are likely to occur in the US.

There are a variety of situations that constitute a state of emergency, including the following:

- Natural disasters like earthquakes, wildfires, hurricanes, extreme temperatures, tornadoes, wildfires, and floods

- Public health crises

- Man-made conflicts such as war

When a state of emergency or other similar event takes place, the appropriate emergency management teams will take action in the affected communities. Response actions are typically organized by the Federal Emergency Management Agency (FEMA).

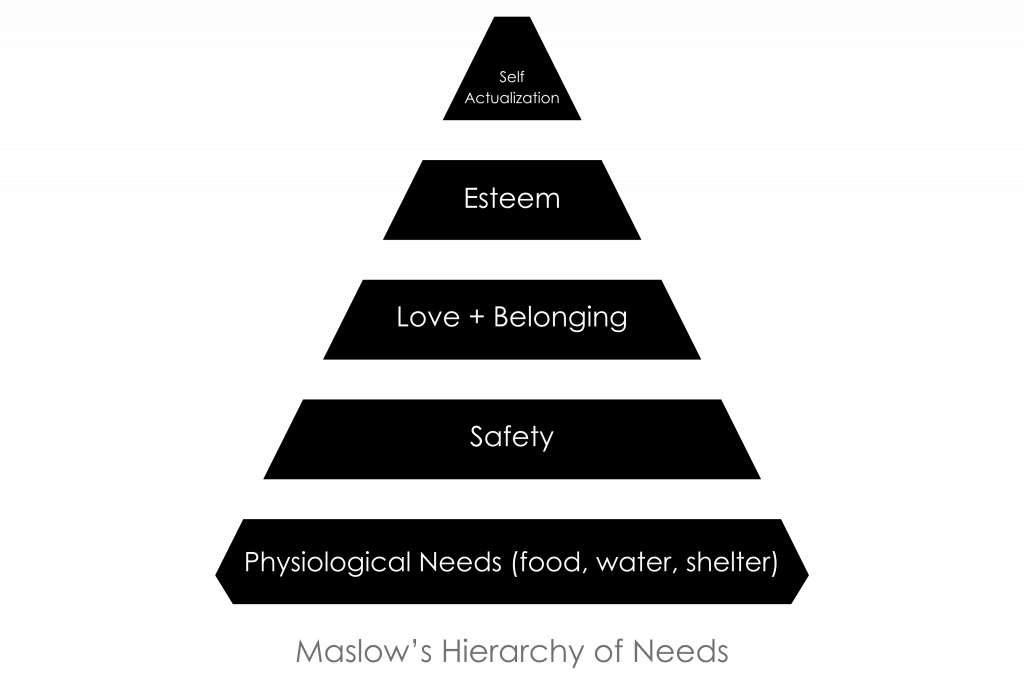

Need for Shelter

When disaster strikes, shelters serve many purposes. It is one of our most basic requirements for survival – according to Maslow’s Hierarchy of Needs, shelter falls under the most essential human need, physiological needs. Temporary shelter is also one of the core clusters recognized by the United Nations for greater coordination in humanitarian crises.

Not only does shelter offer us a place of refuge, but also space for privacy, dignity, security, treatment, and recovery. Temporary shelter rapidly provides this space during the response phase of an emergency and helps allow for a smooth transition to recovery following disaster.

Shelter Application in an Emergency

- Resiliency hubs

- Medical facilities

- Temporary housing

- Storage & distribution centers

- Communication/command centers

Need for Essential Power

Power is essential for access to medical equipment, heating and cooling systems, communication tools, lighting, water supply, and other critical devices. In situations where affected areas are left with disruptions to the local power grid, the need for power can become dire.

The Power of Solar

When considering off-grid power systems, solar offers several advantages. Some of the key benefits of utilizing solar in emergencies include:

- Sustainable power. Solar is a renewable resource that harvests the sun’s energy and stores it in batteries that don’t release harmful emissions.

- No need for fuel resupply. Since solar power is continuously derived from photovoltaic panels, there is no need to source battery systems with fuel.

- Dependability. During times of crisis, it is important to have a system you can rely on to provide power for essential activities.

- User friendly. Solar power systems are very user friendly and require little maintenance.

- Silent. The batteries used in solar power systems are completely silent, unlike the loud and ear damaging roar of a diesel generator.

How Can Pvilion Help?

Pvilion’s Solar Power Integrated Structures (SPIS) integrate solar power into shelters that are designed to meet the specific needs of emergency response. The features of Pvilion’s SPIS include:

It’s important to be prepared for unexpected situations and emergencies. Our focus at Pvilion is to make clean energy and shelter available in any setting, at any time. Pvilion’s Solar Powered Integrated Structures are designed to be durable and easy to use. That way, when the unexpected occurs, communities have easy access to safe and reliable shelter and power as quickly as possible.

30% Incentive Tax Credit

All Pvilion Solar Powered Integrated Structures also qualify for a 30 percent tax credit thanks to the Inflation Reduction Act. Under this act, nonprofits, government agencies, and other tax-exempt entities can still benefit through the elective pay provision. This means purchasers can receive 30 percent of the entire system’s value back, thanks to its solar integration.

To learn more about how the ITC works, click here.

Want to learn more about how Pvilion Solar Powered Integrated Structures can help with your resiliency needs? Get in touch with our solar shelter experts to learn more and receive a free quote.

“Best of Best” | Product Design Award 2023 Winner | Architecture Masterprize

PVILION’S SOLAR FABRIC EVENT KITS

In an effort to replace noisy, polluting diesel generators, Pvilion has created solar-powered fabric kits that can be used to provide event spaces with self-sustaining, environmentally friendly power. The kits are lightweight, flexible, easily folded up, and designed for ease of transport. The solar-powered fabric can be quickly set-up on any surface that receives sunlight and used to power silent, clean-energy battery kits. They are modular and can be scaled to meet different power output needs for event venues.

Location: Brooklyn, United States

Company: Pvilion

Lead Designer: Todd Dalland

Design Team: Colin Touhey, Robert Lerner

To view the award, click here.

Solar Powered Fabric Designer Expands in Industry City, Takes Leading Role in Transformative ʻTrain and Hireʼ Programs Here

December 19, 2023 | Brooklyn Eagle Staff

INDUSTRY CITY — A Brooklyn-based solar-powered fabric designer and manufacturer is following a proven Industry City model of training and hiring from neighboring Brooklyn communities. The company, Pvilion, was founded by Park Slope native Colin Touhey, and recently hosted a ribbon cutting ceremony to celebrate their expansion and grand opening of a new headquarters.

Demonstrating their new technology and introducing an expansion of employees through BlocPower and the Brooklyn Chamber of Commerce, Pvilion held a press conference Wednesday, Dec. 13, in their new headquarters overlooking New York Harbor.

Showing off their new 13,500-square-foot office and manufacturing space in Industry City’s Building 8 marks a huge milestone for the small business. It also celebrates its recent partnership with BlocPower to provide valuable clean energy job training within low-income communities and communities of color to develop the skills needed to build a clean energy future.

“We’re thrilled to celebrate this huge milestone with so many members of the community! The new headquarters will provide enough space to significantly increase our local manufacturing for commercial and defense products. We have already hired more employees to help with production in this new manufacturing space, and we hope to continue to expand and create more jobs in the clean energy space within New York City,” said Colin Touhey, CEO and co-founder of Pvilion.

Through their partnership with BlocPower’s Civilian Climate Corps program, Pvilion will continue to provide green job training in their new space. Additionally, this recent growth has led to the hiring of new full-time employees from BlocPower’s training program to help manufacture clean energy projects.

This grand opening celebrates the small business’s growth, expanding upon 10 years of manufacturing clean energy products in Brooklyn for customers from New York City to Ukraine, Guam, California and Asia. Among their clients are U.S. government projects and major rock bands, whose lights and equipment normally require diesel-fueled generators at the scene of the concert. Now, their solar collecting equipment enables rock bands to be more ‘green’ in major public spaces, like parks.

Following the ceremony, Pvilion held an open house and technology demo and exhibit for guests to tour within the new space. Guests were able to tour a variety of Pvilion’s solar-powered fabric products, battery systems and production processes. The exhibit included opportunities to walk through solar-powered tents and learn more about the social, economic, and carbon impact of each project within New York City.

To view the original article on the Brooklyn Daily Eagle, click here.