PV Magazine | July 27, 2022 | BLAKE MATICH

In some of the world’s most hazardous locations, a resilient and autonomous common denominator is often found – solar energy. From offshore oil rigs to remote mine sites and the frontlines of conflict zones, solar power functions where others fail, and it does so without the need of refuelling or regular maintenance. But what makes solar such a ‘no-brainer’ that even the oil and gas industry must turn to it? And what other hazardous locations can be electrified with solar? Blake Matich reports.

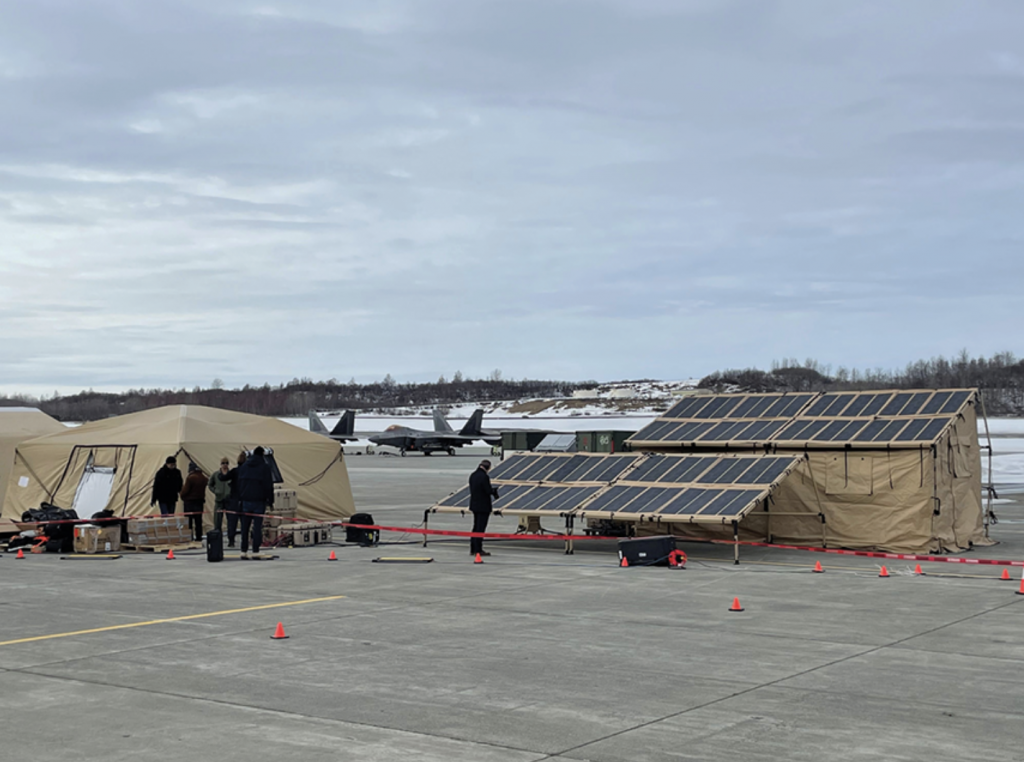

Pvilion’s solar tent structure is designed to provide quick access to both power and shelter in various difficult settings. The solution has been adopted by the US Army, which sees various applications in disaster response, contingency response, emergency preparedness, hurricane relief and humanitarian aid.

Solar panels may seem a juxtaposition in the midst of oilfields and atop offshore oil rigs. But thanks to its resilience and dependability, solar has found a home in some of the world’s most remote and hazardous locations, including those devoted to the extraction of fossil fuels.

“For remote critical power applications, PV is more often than not the only solution,” says Mark Cerasuolo, a director at US-based solar controller company Morningstar. And there is no shortage of remote critical power applications. Cerasuolo puts the global network of oil and gas pipelines at 3.2 million kilometers, featuring over 65,000 extraction and operation sites (9,000 of which are offshore). “Yet the growing influence and adoption of ‘Digital Oilfield’ technologies requires power to run on nearly every mile of pipeline and at every site – from the Indian Ocean floor to the Sahara Desert.”

And yet, while diesel and gas generators require continual refuelling, regular maintenance and often replacement (all extremely expensive tasks in remote and hazardous locations like mines or unmanned offshore platforms), a PV system requires little more than sunshine. “They can run for years without being touched,” added Cerasuolo, who pointed to solar arrays still in operation on satellites that have been in orbit since the 1960s as an example. “PV’s capex is soon offset by its superior opex, and that translates into bottom-line benefits very quickly.”

The digitization of oilfields not only enables increased productivity and savings, but means operations are a whole lot safer. However, these benefits all depend on “PV being the most cost-effective means of reliably powering remote systems and delivering ‘greener oilfield’ benefits.”

Taking an offshore oil platform as an example, a PV system powers valve and motor control, sensor systems, communications, lighting and navigation systems and even bird-deterrence systems. “The last is part of life at sea,” continues Cerasuolo. “Bird droppings are corrosive and can quickly affect machinery on a platform if not managed properly.” Moreover, “offshore platforms often have helidecks for transporting personnel” which are “equipped with powerful lighting systems, and our solar controllers have the load management capabilities these lighting systems require.”

The term “hazardous” doesn’t simply refer to a location’s remoteness or environmental dangers – it’s precisely defined. In North America, Underwriters Laboratories and the Canadian Standards Association use a Class/Division/Groups method, meaning a hazardous location is defined when gases, liquids and vapors (the Class) may be present (the Division) and which include substances such as hydrogen, gasoline, propane and others (the Group). Outside North America, the International Electro-technical Commission and the European Committee for Electro-technical Standardization use a “Zone System.”

Compared to alternatives, PV systems are much better suited to HazLoc standards. Often developers custom-design PV power systems in enclosures and skids for oil and gas customers, with some specializing in explosion-proof container systems where Morningstar’s charge controllers operate for years in a small, sealed space. Cerasuolo noted the technology’s fanless design reduces the potential of harmful vapors and gases flowing over circuitry, as does encapsulating internal components. “It’s quite common for Morningstar to be the second choice in such circumstances,” says Cerasuolo. “After the first controllers installed have failed in the field.”

Solar in conflict zones

It is said that an army marches on its stomach, but as Brooklyn-based solar fabric and structure developer Pvilion’s Julia Fowler told pv magazine, the US Army is already marching on its solar technology. “We have fully developed a turnkey solar powered integrated structure that provides shelter, power, and climate conditioning in remote and austere environments.”

In short, Pvilion developed a solar tent, a structure as easy to put up as it is to pack away and “fully independently powered.” While technology has advanced rapidly in recent decades, the tent doesn’t seem to have evolved much beyond the classic hutchie – a stick with a sheet draped over it. But Pvilion likes to think of its tents as “the Swiss Army knife of tents, as they are designed to provide more with less.”

“Not only do they provide shelter, but they provide power, convenience, adaptability, heating and cooling, and protection from the elements… with the goal of maximizing mission-objective readiness.” Of course, those missions are not always of the combat variety. “Our structures provide solutions in many different settings and applications,” says Fowler. “To name a few, disaster response, contingency response, emergency preparedness, hurricane relief, humanitarian aid, refugee centers.”

Part of this variability is the solar tent’s position in the energy-water nexus demonstrated by “Project Arcwater”, which sees the tent’s solar energy generation used to harvest water in an agile combat deployment situation.

In March 2022, Senior Master Sgt. Brent Kenney of the 52nd Fighter Wing, Spangdahlem Air Base, Germany, received the 2022 Spark Tank trophy at the Air Force Association’s Warfare Symposium for “Project Arcwater”. In Kenney’s estimation, a three-day 30-person mission that would normally cost $40,000 would, with the help of the solar tent and its powering of other tech such as the water harvester, cost under $600 while providing the same combat capability.

That 98% cost reduction is put down to using 83% less fuel, less cargo space, no longer paying for water, and all with a package that is quicker and lighter. The water harvester alone negates the need for a new pallet of water every six days, representing a $9 million saving annually across the US Air Force.

Additionally, the solar structures come with ready-to-use battery kits further reducing dependency on diesel. “The kits provide modular 4 kWh battery kits, and are typically used in multiples of six, for a total of 24 kWh of readily available power,” says Fowler.

High-altitude installations

The Indian government’s Intended Nationally Determined Contributions (INDCs) aims for the country to reach 40% cumulative installed electric capacity from non-fossil fuel-based energies by 2030. But as one of the most densely populated countries in the world, India will have to take advantage of its high-altitude regions to reach its ambitious solar targets.

However, Saurabh Nirgudkar, a project engineer at Evergy Engineering India who contributed to the World Bank’s “Live Wire” series on “Installing Solar Power Plants in Snowbound Areas: Lessons from Himachal Pradesh, India,” told pv magazine that there is no shortage of hazards and obstacles when it comes to snowbound and high-altitude solar projects.

The projects themselves are susceptible to high winds capable of taking the module off the racking systems and even compromising the stability of the mounting systems themselves. Moreover, the modules need to be rated up to 4,000 m altitude while also being capable of operating at extremely low temperatures and withstanding a minimum of 5,400 Pascal of pressure from wind and snowloads.

Nirgudkar pointed to a number of ways to overcome these challenges, such as the addition of back rails to mounting structures and the use of gravity weights instead of deep drilling in fragile snowbound soil strata. Moreover, due to the high UV penetration, rain and snow, cabling should be installed within the mounting structure and under the PV modules. Any exposed cabling should sport additional plastic piping.

This notion was seconded by Olivier Haldi, head of business development for Stäubli Electrical Connectors, a company which has been at the forefront of solutions for PV in hazardous locations from projects in Antarctica, to projects 2,500 meters above sea level on the Muttsee dam in Switzerland and even as high as 5,000 meters above sea level in Chile’s Atacama Desert. Haldi told pv magazine that, “Generally speaking, if your product (connector) is already at or close to the limit under ‘normal’ conditions, it’s not designed for and won’t manage harsh environments. So you need a certain margin in your product design, technology and material.”

Combiner boxes, transformers and inverters (preferably string) also require shelter under panels and extra protection in case of exposure. What is more, these often remote and precarious locations also pose a range of logistical challenges, not only for installation but also offtake. Such challenges necessitate rigorous planning and site selection criteria.

While engineers have worked out methods to overcome the challenges of high-altitude, there remains the begging question of why high-altitude regions are suitable for PV in the first place?

For anyone who has spent time at altitude the answer is straightforward. Not only do PV systems prefer cooler temperatures, but the clear open skies above the cloud line along with higher levels of irradiance ensure greater yields. Take the focus area of the World Bank study, the Spiti Valley, which “receives almost 300 days of clear sunshine annually” and considering “the land at such high altitudes is predominantly barren and slopy terrain of low value, this cuts down on land cost significantly.”

Nirgudkar believes “there is a bright future for such projects. Huge steps are already being taken in this direction with Minister of Power India and the Ministry of New and Renewable Energy (MNRE) looking at the possibility of setting up a 10 GW renewable energy project in Leh, Ladakh, which is at an altitude of more than 3,500 m. A battery energy storage system of 12 GWh is also proposed to be installed.”

“The local community also benefits from these projects,” continued Nirgudkar. Benefits include employment opportunities and economic boosts, not to mention a chance to alleviate a dependency on expensive diesel fuel which has come as a result of “erratic electricity supply.”

To view the original article, click here.